End Rust: Real-World Applications for ECK Across Industries

Posted by Austin Hardware on Oct 6th 2025

End Rust: Real-World Applications for ECK Across Industries

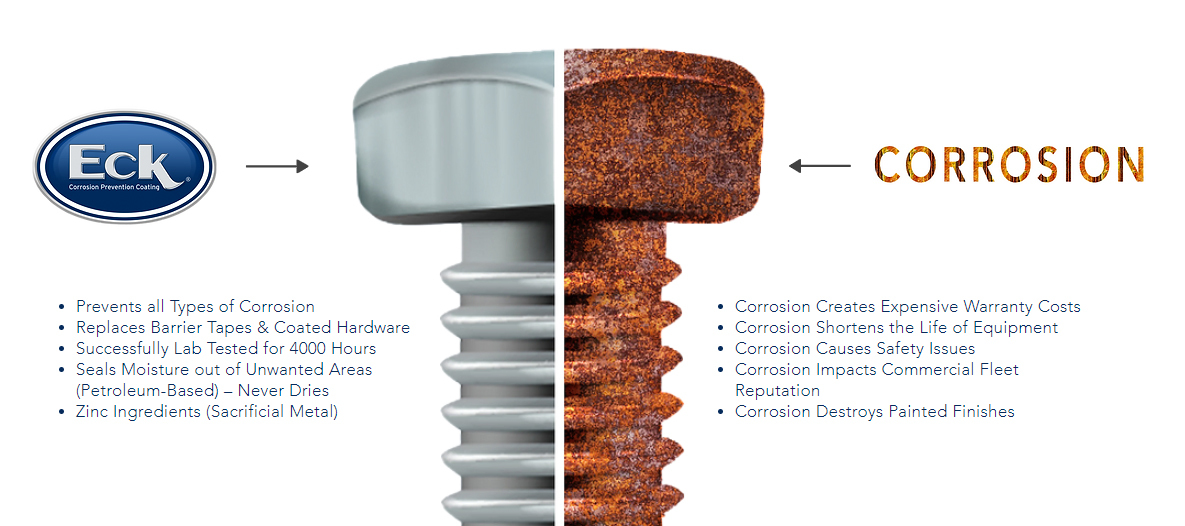

Rust and corrosion aren’t just cosmetic issues. They’re costly threats to safety, performance, and equipment longevity. Left untreated, corrosion can cause hardware to seize, weaken structural integrity, and lead to expensive downtime or repairs. ECK Corrosion Prevention Coating is the solution for industries that count on reliable equipment daily. Engineered for broad use, ECK provides durable protection that helps reduce repair and replacement costs, avoid warranty issues, and extend the service life of critical components.

What makes ECK unique is its remarkable versatility

Across industries as diverse as automotive, trailers, emergency vehicles, HVAC, aircraft, fabrication, electrical, marine, RVs, railways, and consumer products, the coating has proven to be a reliable defense against corrosion.

Cargo trailer hardware, for instance, is constantly exposed to road salt and weather extremes, while hinges and fasteners on boats face the daily challenge of saltwater spray. Electrical connectors, playground equipment, outdoor furniture, and even manufacturing machinery are all susceptible to corrosion in their own ways. ECK safeguards these applications, keeping components functional and extending their usable life.

How ECK Works

ECK is more than just a coating—it’s a technical barrier against corrosion. Its zinc-rich formula creates a sacrificial layer that protects the underlying metal, slowing oxidation and preventing rust from spreading. Once applied, ECK bonds tightly to metal surfaces, sealing out moisture, oxygen, and contaminants that typically trigger corrosion. It also has dielectric properties, making it safe for electrical connections by preventing arcing and ensuring conductivity is not compromised. This combination of protective mechanisms makes ECK highly effective in demanding environments where traditional coatings or paints often fail.

ECK’s packaging options enhance practicality

Available in squeeze tubes, aerosols, and quart cans, Eck offers a solution for every scale of application. A squeeze tube allows precise use on small areas or electrical connections, while an aerosol makes it easy to apply even coverage across hardware or machinery. For larger or industrial jobs, quart cans provide the bulk application needed to coat multiple parts or assemblies.

This flexibility ensures that whether you are a DIY user working on a small project or a manufacturer maintaining an entire production line, ECK has an option suited to your needs.

The advantages of ECK go far beyond preventing rust

The coating ensures bolts, fasteners, and connectors remain serviceable by protecting hardware from seizing. That reliability translates directly into cost savings, as fewer repairs and warranty claims are required over the equipment's lifespan. In turn, machinery, vehicles, and consumer products retain their structural integrity and function more safely and effectively, reducing risk and downtime.

In today’s world, where equipment must deliver maximum performance while budgets are under constant pressure, corrosion protection is essential. ECK Corrosion Prevention Coating offers an innovative, cost-effective way to protect valuable assets across industries. From cargo trailers to playgrounds, HVAC systems to manufacturing plants, ECK ensures that rust won’t hinder productivity or safety.

To learn more about Eck or any of Austin Hardware’s products or services, please visit our newly redesigned website or contact one of our 11 nationwide locations nearest you.