Austin Guaranteed Engineered Solutions®

At Austin Hardware, we are proud to hold ourselves to a standard unforeseen in the industrial solutions industry. Our premium inventory paired with the unmatched capabilities of our Austin Engineering team means OEMs are guaranteed a value-added solution when they choose to partner with us.

With over 100 years of combined experience, our team is equipped to improve design, functionality, and user experience with innovative, custom-made hardware solutions. Not only that, but we have a proven track record for driving cost reduction through assembly time, manufacturing capabilities, and sourcing. Read on to discover the benefits that await your manufacturing business when you choose to invest in Austin Engineered Solutions.

Our process

Ready to discover the Austin Hardware difference with our innovative and collaborative engineering team? The process is simple and designed to get you the product you need, every time. Our team is ready to work alongside you, collaborating with you during every step of the process.

Research and Development

Our first step in delivering you the solution you need for your business is working together to understand your needs and help identify your goals. During this step, we take measures to gather information on your biggest issues and analyze any strategies you may have tried in the past. This fact-finding session is the key first move in engineering the right solution for you.

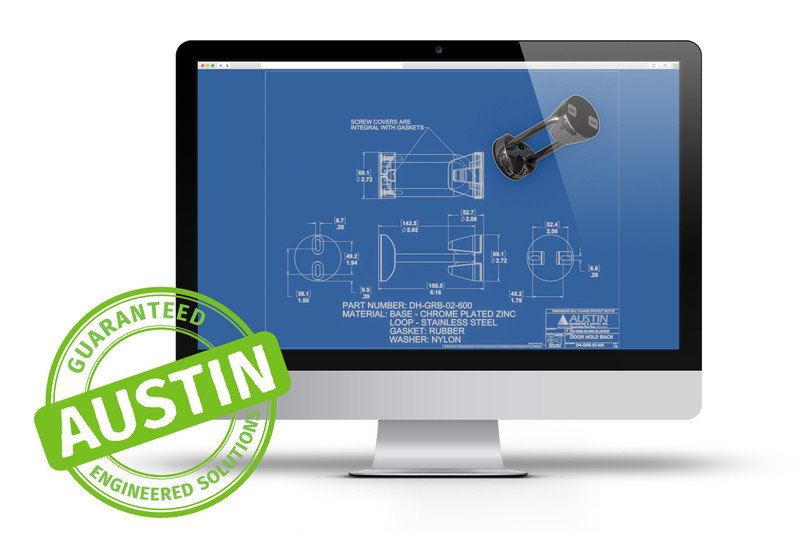

Design Review and Approval

This is the part where the magic happens. As your partner, you have the opportunity to be very involved or completely hands off through each step of this engineering process as we work through different designs and amend issues as we see fit. During the design phase, we’ll produce deliverables ranging from sketches, CAD files/rendering, written requirements, or prototypes. Our process is an iterative one—as we create and analyze different designs, we have the opportunity to work out problems, make improvements and ensure a successful launch.

Analysis, Testing, And Validation

Prior to launching, we will conduct any necessary testing or validation to ensure the solution checks all the boxes you need. Products can be designed and tested to meet your specific needs, standard industry specifications, or common best practice recommendations for the application. With the production of samples, we can also conduct testing such as load rating, corrosion resistance, cycle reliability, or any other performance specifications that are critical to your application.

Product Launch

You are one step away from integrating a completely custom solution to your business! Once our design passes an internal design validation review, it's time to move toward production. During this phase, we prove the integrity of the design with the first article production samples. These samples give us the opportunity to visualize what the production parts will look like and perform durability testing to verify all requirements have been met or exceeded. After approval, the parts are released to full production.

featured Austin Guaranteed Engineered solutions®

Front Drawer Release

Welcome to the future of hardware solutions: Austin Hardware’s patented Front Drawer Release (FDR) System is innovative, flexible, and allows for one-handed operation while remaining secure.

The FDR was engineered to meet a common issue faced by those in the industry: in applications such as moving vehicles, you need to secure heavy duty drawers with a latch system but also keep them easily accessible for occupants. The FDR tackles this obstacle with its one-handed operation and latching capabilities in both the fully closed and fully open positions.

LifeDefender Cabinets

When it comes to constructing emergency response vehicles, there’s no room for compromise on safety. That’s why we engineered LifeDefender™, our patented cabinet Security Frames for emergency response vehicles designed to uphold optimum occupant safety.

We collaborated with emergency vehicle manufacturers and industry professionals to set and meet rigorous safety standards. The result? Crash tested security frames that ensure patient and EMS worker safety on the move, and even in case of an accident.

Genesis Gas Springs

We made finding the perfect gas spring for your application easy with our Genesis™ Gas Springs. Incredibly high-quality and reliable, these gas springs are equipped to handle a wide variety of industrial applications, from automotive manufacturing to the medical and aircraft industry. Plus, they come in a variety of different load capacities and dimensions to fit every need. Whether you’re installing gas springs in car trunk doors or looking for the perfect solution to outfit industrial machinery, Genesis Gas springs are equipped for the job.

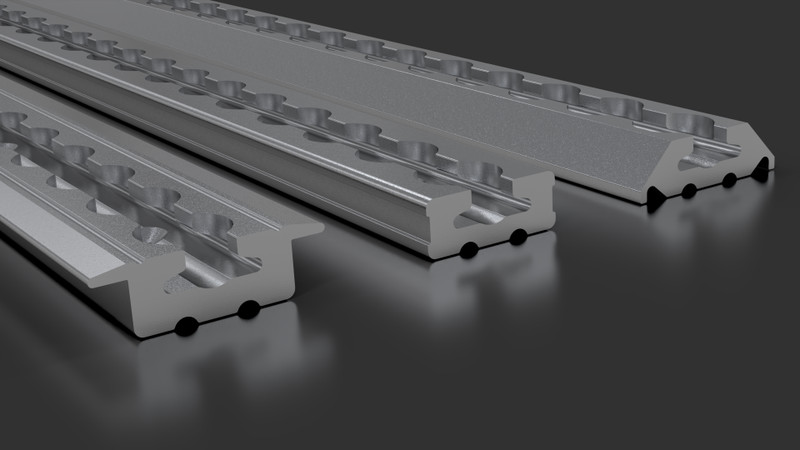

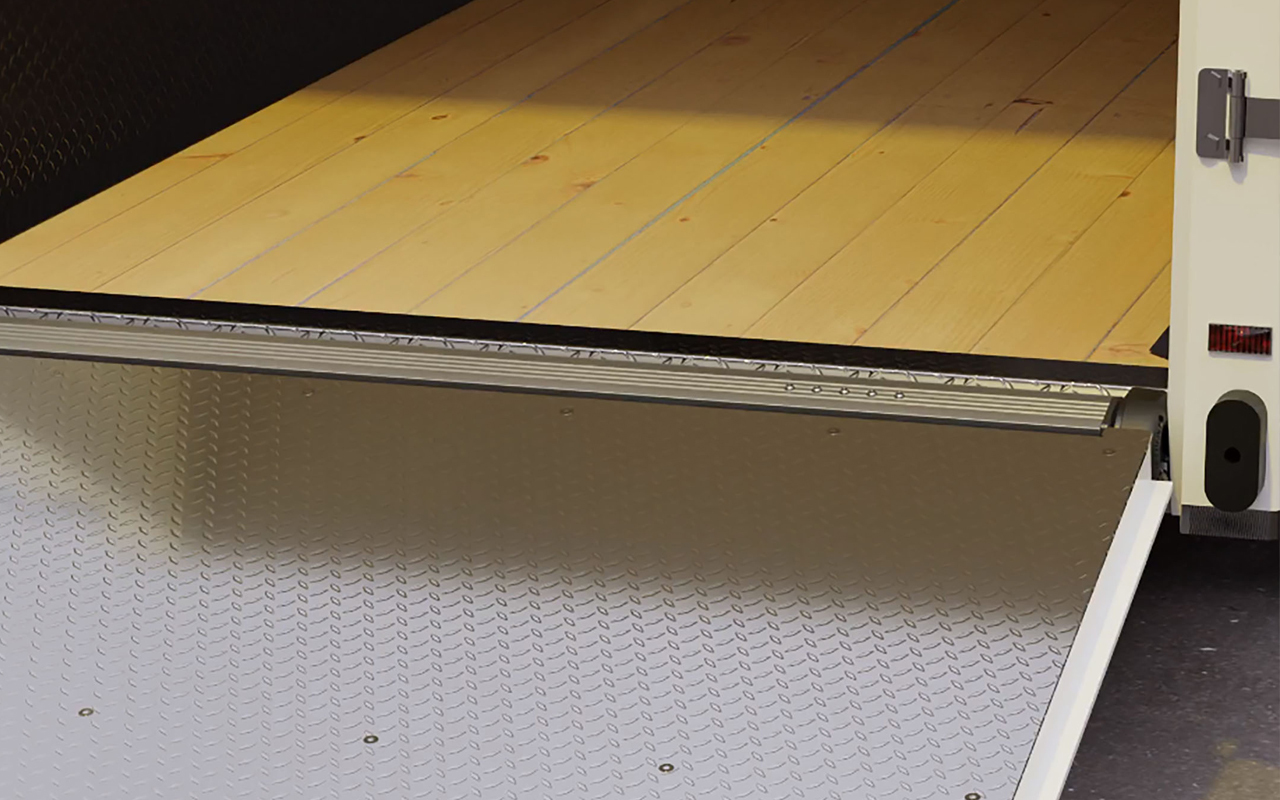

Safe Assist

This heavy duty ramp door assist is revolutionizing safety when it comes to heavy ramp doors. The Safe Assist completely removes the physical strain of opening and closing heavy ramp doors by rendering it virtually weightless—all without the need for dangerous cables that can snap or create a tripping hazard. With the Safe Assist, all that’s required to lift and lower heavy ramp doors is the strength of a single finger throughout the complete motion.

Our Austin Engineered Solutions don’t stop here—explore our full stock of innovative solutions, ranging from convenient ventilation solutions, to drag wheels, and more.