Eck Complete Corrosion Protection

Meet Eck: Austin Hardware’s corrosion preventative coating engineered to protect equipment from costly damage caused rust and various types of corrosion. Extensively tested and made in the USA, Eck works by creating a protective barrier between dissimilar metals like steel and aluminum, which left untreated would corrode and shorten the equipment’s life.

Why is Eck Different?

- Eck is formulated to outperform industry-standard silicone products, washers/rubber spacers and other corrosion preventers. These other products are not effective solutions because they do not actually prevent the electrolytic reaction that causes corrosion.

- Eck is tough on corrosion but will not ruin your paint job. Three of the world’s largest commercial paint manufacturers endorse the use of Eck for corrosion prevention in industries like automobile and truck manufacturing.

- Not only is Eck effective on all types of metals, but it is also perfect for use on electrical connectors.

- It comes in squeeze tubes, aerosol, and quart cans, so it is versatile and meets any project’s needs.

WHY ECK WORKS

Eck has been meticulously lab tested for 4,000 to guarantee ultimate protection against corrosion. The result? A revolutionary formula you can trust to extend equipment life and save money in the long run.

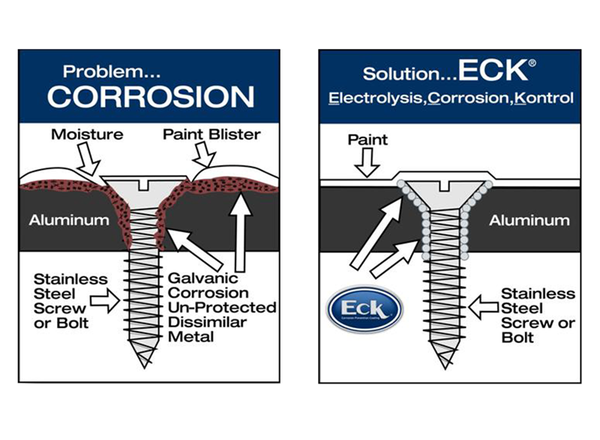

Galvanic corrosion occurs when two dissimilar metals are fastened together and are both exposed to a common electrolyte. Since the two metals have different electrical potentials, one metal will erode faster and a costly chemical reaction ensues.

To understand this process, it helps to know how metals interact on the galvanic scale:

Anodic (Active) Metals: Metals higher on the galvanic chart—like magnesium or zinc—are more likely to corrode when paired with metals further down the list.

Cathodic (Noble) Metals: Metals lower on the chart—such as stainless steel or copper—are less likely to corrode and instead accelerate the corrosion of the more active metal.

Galvanic Potential: The greater the difference in electrical potential between the two metals, the higher the risk and speed of corrosion for the anodic (less noble) metal.

When fasteners or components made from these different metals are joined without protection, the resulting galvanic reaction can mean rapid degradation, seized hardware, or even structural failure.

Eck stops this process in its tracks by creating a barrier between the two metals, using Zinc dust and Zinc powder as the sacrificial metal. By absorbing corrosive energy, Eck prevents all types of degradation, including:

• Galvanic corrosion (dissimilar metal corrosion)

• Magnesium chloride corrosion

• Calcium chloride corrosion

• Hardware/fastener seizing

Why do you need to minimize corrosion?

It’s important to understand that rust and corrosion are not only the start of aesthetic degradation, but warning bells for much bigger problems: weakening of metals, disintegration, safety issues, and expensive warranty claims.

Dissimilar metal corrosion can cause bridges to collapse, chemical plant leaks, and endless other hazards if left untreated. Taking action by investing in a corrosion barrier early on will save you from massive headaches of costly repairs, irreversible damage and preventable safety hazards. For example, corrosion poses a big risk for passenger and driver safety in industrial vehicles, which are manufactured from aluminum using stainless steel fasteners and hardware.

That’s why we always recommend treating your metal equipment and machinery with an effective corrosion barrier like Eck. Using a lab tested Zinc formula, Eck produces a superior protective coating that creates a barrier between the dissimilar metals and seals out moisture.

Eck's Endless Applications

Wherever dissimilar metals are placed next to each other, a corrosion barrier like Eck is necessary. This means there is an endless list of applications and reasons to keep Eck in your toolbox.

Industries

Eck is highly beneficial for manufacturing products in industries such as:

• Automotive

• Trailer

• Emergency vehicles

• Machinery

• HVAC

• Fabrication

• Aircraft

• Electrical

• Marine

• Recreational Vehicles

• Railway

• Consumer

Applications

Corrosion isn’t picky—it can crop up in nearly every industry or environment where dissimilar metals meet moisture or electrolytes. Here are some real-world situations where galvanic corrosion is notorious for causing trouble, and where using a protective barrier like Eck can make all the difference:

• Cargo, utility, and travel trailers

• Handles, fasteners, hinges on vehicles and boats

• Undercarriages of trucks

• Fire and emergency apparatus

• Industrial and agriculture equipment

• Electrical connections and light (Eck is dielectric)

• Machines and manufacturing equipment

• Outdoor furniture

• Playground equipment

• Lawn equipment

• BBQ grills

SHOP ECK Products

resources

Safe Use & Product Warnings

• DANGER! EXTREMELY FLAMMABLE LIQUID AND VAPOR. VAPORS MAY CAUSE FLASH FIRE. VAPOR HARMFUL. CONTENTS UNDER PRESSURE

• MAY CAUSE RESPIRATORY IRRITATION

• MAY CAUSE DAMAGE TO ORGANS THROUGH PROLONGED OR REPEATED EXPOSURE

• KEEP OUT OF REACH OF CHILDREN

Contains: Solvent Naphtha 64742-95-6, Zinc Powder 7440-66-6, Aluminum Stearate 637-12-7, Additive, Dimethyl Disulfoxyde 67-68-5.

OTHER INGREDIENTS: “Contents Partially Unknown”.

WARNING Flammable liquid and vapor. May cause respiratory irritation. May cause damage to organs through prolonged or repeated exposure.

Prevention: Use only with adequate ventilation. Do not breathe dust/vapors/spray mist. Avoid contact with eyes/skin/ clothing. Wear protective gloves/clothing/glasses. Keep away from heat/sparks/open flames/hot surfaces. Do not eat/ drink/smoke when using this product.

Ground/bond container and receiving equipment. Take precautionary measures against static discharge. Use only non-sparking tools.

Response: In case of fire, use extinguishing powder or water spray. Immediately contact a doctor or POISON CONTROL CENTER if you feel unwell. If medical attention is needed, have product label at hand. IF IN EYES: Rinse with water for several minutes. Remove contact lenses if present. If eye irritation persists seek medical attention. IF SWALLOWED: Rinse mouth with water. Do not induce vomiting. IF INHALED: Remove to fresh air. IF ON SKIN: Wash thoroughly with water. Remove all contaminated clothing. Storage: Keep container tightly closed. Store in a well ventilated place. Keep cool. Protect from sunlight and do not expose to temperatures exceeding 50˚C/122˚F. Disposal: Dispose of product in accordance with local/regional/national/international regulations. Additional

Precaution Statements: Vapors may ignite explosively and cause a flash fire. Prevent buildup of vapors by opening windows and doors to achieve cross ventilation. Reports have associated repeated and prolonged occupational overexposure to solvents with permanent brain and nervous system damage. Intentional misuse by deliberately inhaling the contents may be harmful or fatal. In cases where short and/or long-term overexposure conditions exist, a charcoal filter respirator should be worn. Follow respirator manufacturer's directions for use.

Read Safety Data Sheet Before Use