Austin Hardware's VMI & CMI Programs

Eliminate out-of-stocks. Avoid overstocks. Save time and resources.

In today's market, many companies are looking for help managing your inventory and that is where Austin Hardware can step in. Do you want to streamline purchasing and stocking processes, ensure the right hardware inventory is on hand when you need it? Austin’s Vendor Managed Inventory (VMI) program is designed to improve parts availability and reduce expenses.

Are you experiencing these common inventory management issues? Let Austin Hardware® help you get the right quality and quantity on the shelf at the right time.

- Running out of parts

- Manufacturing lines shut down

- Multiple purchase orders

- Falling short on inventory turn goals

- Little to no forecasting tools

- Managing inventory via spreadsheets or manually

What is Vendor Managed Inventory?

Vendor Managed Inventory (VMI) is a collaborative approach where suppliers take charge of managing their customers' inventory. This partnership involves the supplier overseeing stock levels, predicting demand, and automatically replenishing inventory to maintain optimal availability while keeping costs in check.

In a VMI setup, suppliers gain access to their customers' real-time inventory data. They work closely with customers to establish suitable stock levels, reorder points, and order quantities based on mutually agreed targets. The supplier actively monitors inventory, spots potential issues, and continuously refines processes to boost overall supply chain efficiency.

By transferring inventory management responsibilities to the supplier, VMI allows customers to concentrate on their core business activities. This arrangement provides customers with the assurance that essential parts and materials will be available when and where they're needed.

VMI tends to be most effective for items that are ordered frequently and have relatively stable demand. It works best with strategic suppliers who have extensive inventory capabilities to consistently meet customer needs.

The Benefits of Austin Hardware's VMI Programs

• Saves You Time (Time = Money)

• Reduces Stock-outs for your production inventory

• Prevents Over-Stock

• Vendor Consolidation

• Reduces Number of Purchase Orders

• Reduces Errors

• Helps Eliminate Manufacturing Line Down Times

• State of the Art Forecasting Tools

• Reporting & Quarterly Audit

• Custom Kitting

• Eliminates Spreadsheets

• Streamlines Multiple Department Activities

Completely Customizable Display Options for Your Business

Custom Kanban

Storage System

Bin Stocking & Racking Options

Mobile Bin Stocking & Racking Options

Mobile Bin Stocking & Racking Options

VMI Vending Solutions

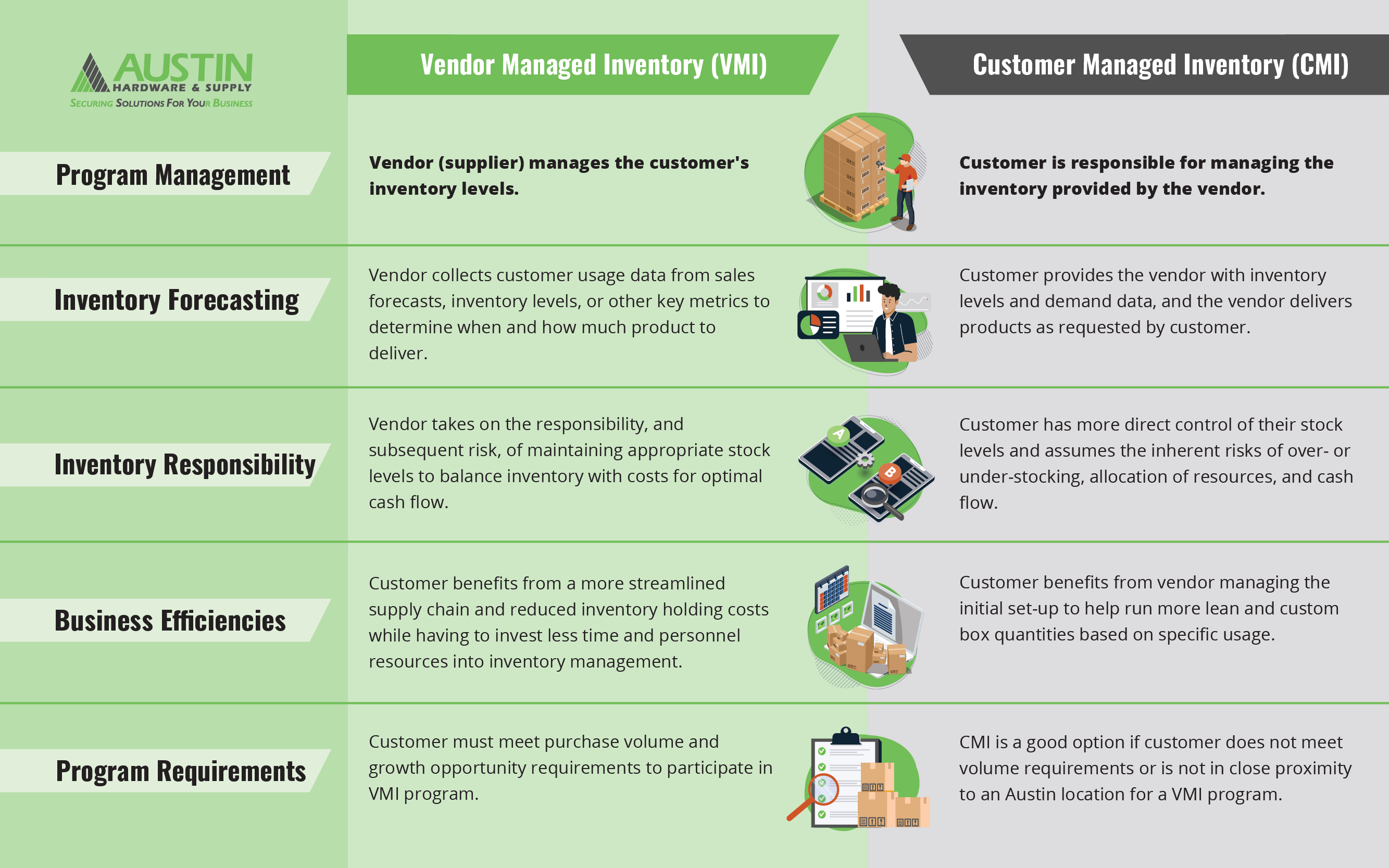

VMI vs CMI

The Key Differences and What Solution is Right for Your Business

How to Choose a VMI or CMI Partner

The Right Partner Makes a HUGE Difference. The selection of a VMI or CMI provider is significant. You're engaging in a relationship with a PARTNER to help manage replenishment. This partner serves as an extension of your team and just like you would with any new hire, knowing you're making the right decision is critical.

Things you will need to know include:

- How much experience does this partner have with VMI and CMI?

- What is their technology platform?

- What KPIs do they measure, and what will reporting look like?

- How do they manage stock levels?

- How do they handle changes in inventory requirements?

- Do they offer other value-added services, such as custom packaging or kitting?

Auto-Replenishment App

Austin Hardware uses a next-gen VMI/CMI app to streamline point-of-use replenishment for our customers using our VMI program. It is safe, used by several top distributors, and helps your business run efficiently at all times. With our easy scanning app, the VMI sales team can become 4-10x more efficient.

Efficiency

10x faster than replenishing with spreadsheets or ecommerce. One scan captures company, item, package, quantity and location.

Consolidation

Spend 90% less on procurement by eliminating paper POs and moving to consolidated digital POs.

Optimized Turns

Optimize inventory with Min/Max Tuning analytics. Eliminate stockouts while reducing inventory up to 73% and decrease carrying costs.

Cutting Edge Technology

Reduce inventory, stockouts, and carrying costs with autoreplenishment technologies including SensorBins, Electronic Shelf Labels, RFID, QR code scans.

Robust Reporting

85 customizable reports to track counting, ordering, items, suggested orders, and more. Reports can be set up with email alerts for greater visibility.

Flexible Solution

Whether replenishing consigned or customer-owned inventory, we can customize the program to meet your needs.

Connect with a VMI Expert