Industrial Series – Heavy-Duty Handles, Latches, and Hinges: Building Industrial Equipment That Lasts

Posted by Austin Hardware on Jan 29th 2026

Industrial Series – Heavy-Duty Handles, Latches, and Hinges: Building Industrial Equipment That Lasts

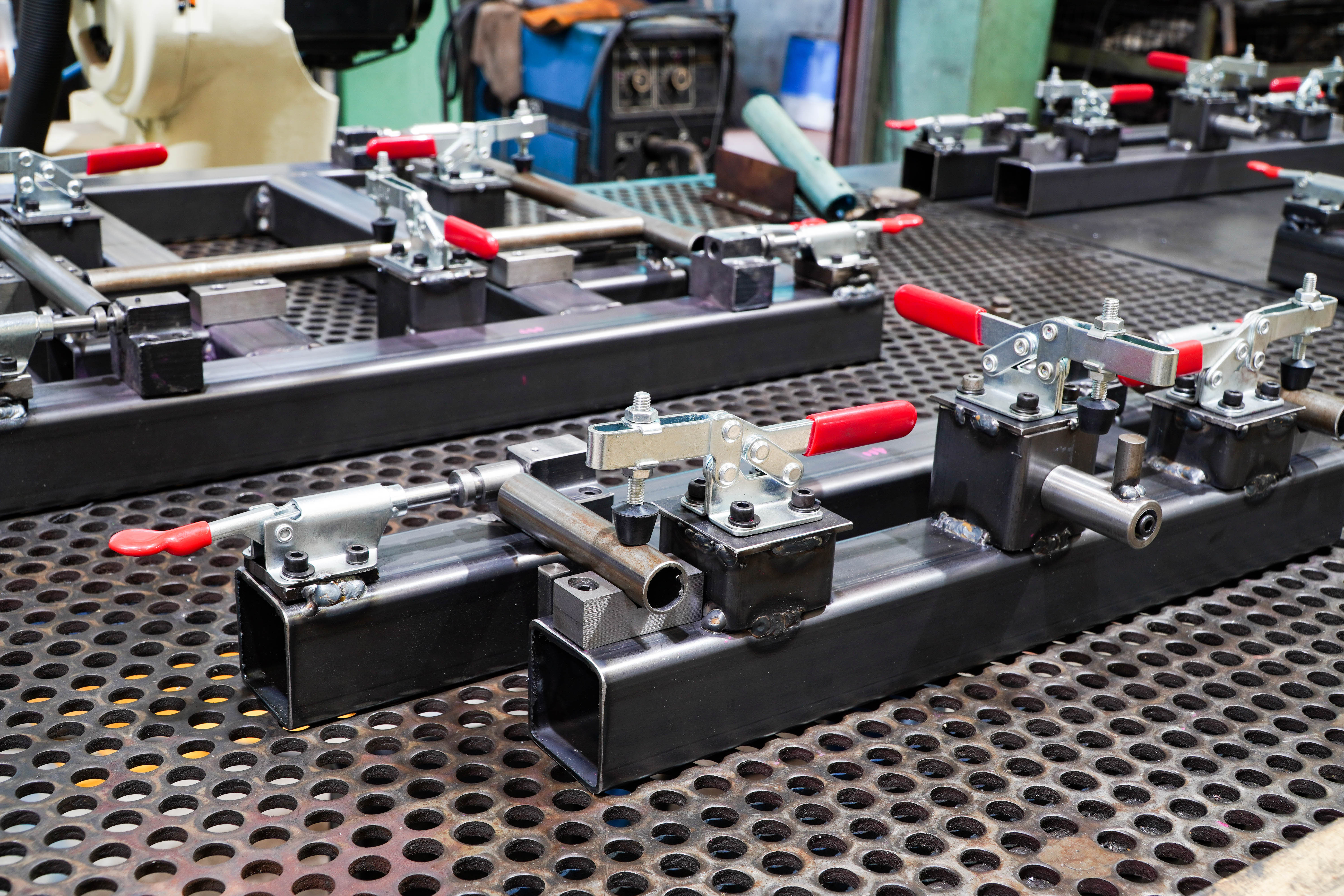

Industrial machinery is built from many critical components. The most visible are engines, motors, and electronics that drive the equipment, as well as other structural elements. Equally as important, but often overlooked, is the industrial hardware, including heavy-duty machine handles, latches, and hinges. These components play a major role in equipment performance, longevity, and safe operation.

Although OEM fabrication hardware may not always be top of mind during the design and manufacturing process, these are the parts operators interact with most. Handles are pulled thousands of times, latches are opened and closed every shift, and hinges must support heavy doors and panels without fail. Poor-quality industrial hardware can lead to downtime, safety risks, and premature equipment failure. That’s why specifying high-quality OEM fabrication hardware is essential—it improves durability, reliability, and overall machine performance.

How Quality Handles, Latches, and Hinges Improve Machine Performance and Durability

Industrial environments are demanding. In addition to continuous use, machinery must withstand vibration, temperature extremes, moisture, chemicals, and dust. Over time, inferior machine handles, latches, and hinges loosen, corrode, or break.

High-quality industrial hardware is engineered specifically for these conditions. Materials such as stainless steel, zinc alloys, reinforced polymers, and corrosion-resistant coatings help prevent wear and environmental damage. Precision manufacturing ensures tight tolerances, reducing misalignment and fatigue.

When a latch fails on an electrical enclosure or a hinge breaks on a service panel, the result goes beyond inconvenience. These failures can expose components, create safety hazards, and cause costly downtime. Investing in durable OEM fabrication hardware helps protect the entire system.

Machine Handles: More Than Just a Grip

Machine handles are the primary point of contact between operators and equipment. They directly affect how easily, safely, and efficiently workers interact with machinery. In industrial environments, good handle design is essential. Qualities to look for in high-level machinery handles include:

- Ergonomic design: Comfortable shapes and textured surfaces reduce strain and improve grip, even with gloves or in wet or oily conditions.

- High load capacity: Strong materials and construction allow handles to support heavy panels and doors without bending or cracking.

- Environmental resistance: UV-stable plastics and corrosion-resistant metals maintain performance in harsh environments.

Low-quality handles often become slippery, brittle, or loose. This can lead to operator frustration, dropped panels, pinched fingers, and repetitive strain injuries—issues that directly affect productivity and safety.

Latches: Securing Performance and Safety

Latches play a vital role in securing machine enclosures, access doors, and panels. They protect internal components from contaminants, prevent unauthorized access, and help ensure compliance with safety standards. Buyers should look for:

- Consistent clamping force: Keeps doors and panels closed despite vibration or pressure changes.

- Precision engagement: Ensures smooth, reliable operation and reduces wear on mating surfaces.

- Environmental sealing: When paired with gaskets, quality latches help maintain IP ratings by keeping out dust, moisture, and chemicals.

In many applications, latches are integral to safety systems, interlocks, or lockout/tagout procedures. A failed latch can compromise these safeguards, increasing the risk of accidents or regulatory violations. OEM fabrication hardware designed for specific environments—such as compression latches for vibration-heavy machinery or cam latches for quick access—ensures reliable, secure operation.

Hinges: Ensuring Smooth Movement and Long-Term Reliability

Hinges are another critical component of industrial hardware. They often support heavy doors, panels, hatches, and covers. Over time, poor-quality hinges can wear out, sag, seize, or fail. High-quality hinges are designed with:

- Proper load ratings: To support doors and panels without deformation.

- Durable materials and finishes: To resist corrosion, galling, and fatigue.

- Smooth, consistent motion: To reduce stress on surrounding components and improve usability.

A sagging door can compromise sealing, misalign latches, and expose internal systems to contaminants. Quality hinges preserve alignment and extend the life of enclosures and machinery.

The True Expense Behind Low-Cost Industrial Hardware

Choosing low-cost industrial hardware may seem economical at first, but it often leads to:

- Higher maintenance and repair costs

- More frequent component replacements

- Increased risk of safety incidents

- More downtime and lost productivity

A latch that fails once a year may be inexpensive to replace, but if it causes a production stoppage or safety issue, the true cost multiplies quickly. Over the lifespan of a machine, these hidden costs often exceed the initial savings.

Investing in high-quality OEM fabrication hardware reduces total cost of ownership by minimizing failures, improving reliability, and extending equipment life.

OEM Fabrication Hardware: Designed for the Application

One of the most important factors in industrial hardware performance is selecting the right component for the application. OEM fabrication hardware is designed with specific industries, environments, and operational demands in mind.

OEM-grade components offer:

- Customization options: Size, material, finish, mounting style, and locking mechanisms tailored to the machine.

- Compliance with standards: Meeting safety, hygiene, and environmental regulations.

- Consistency and reliability: Delivering dependable performance across production runs.

Building for the Long Term

Industrial machinery is a capital investment expected to operate for years with minimal downtime. Every component choice—including machine handles, latches, and hinges—is important.

Machine performance isn’t just about speed or output. Uptime, reliability, and ease of use are equally critical. Here, industrial hardware plays a major role. A latch that opens smoothly and closes securely saves operators time and reduces frustration. A sturdy handle inspires confidence and improves workflow. A hinge that moves effortlessly and maintains alignment keeps enclosures secure and accessible. High-quality industrial hardware makes a significant contribution to:

- Longer equipment lifespan

- Lower total cost of ownership

- Improved operator safety and comfort

- Higher customer satisfaction

These benefits extend beyond individual machines, strengthening brand reputation, reducing warranty claims, and supporting more efficient operations.

The impact of industrial hardware on durability and performance is substantial. Machine handles, latches, and hinges are the everyday touchpoints between people and equipment, and their quality directly affects safety, reliability, and efficiency. By investing in high-quality OEM fabrication hardware, manufacturers protect their equipment, enhance usability, and ensure long-term performance in real-world industrial environments. When uptime is critical and safety is non-negotiable, it’s often the smallest components that make the biggest difference.

By working with experienced hardware manufacturers and suppliers, such as Austin Hardware, equipment designers can ensure their handles, latches, and hinges meet the machine’s requirements rather than forcing generic components into specialized applications. Austin Hardware partners with leading industrial hardware manufacturers, including Southco, Eberhard, A.L. Hansen, and others, to provide top-tier solutions for your machinery. Our in-house engineers are also available to assist in selecting the right solutions tailored to your needs—whether it’s a stock item, a modified product, or a custom development from start to finish. For more information on how Austin Hardware can help you select the highest-quality handles, latches, and hinges for your industrial machinery, please visit our website or contact one of our 12 locations nearest you.